ppm meter hydroponics

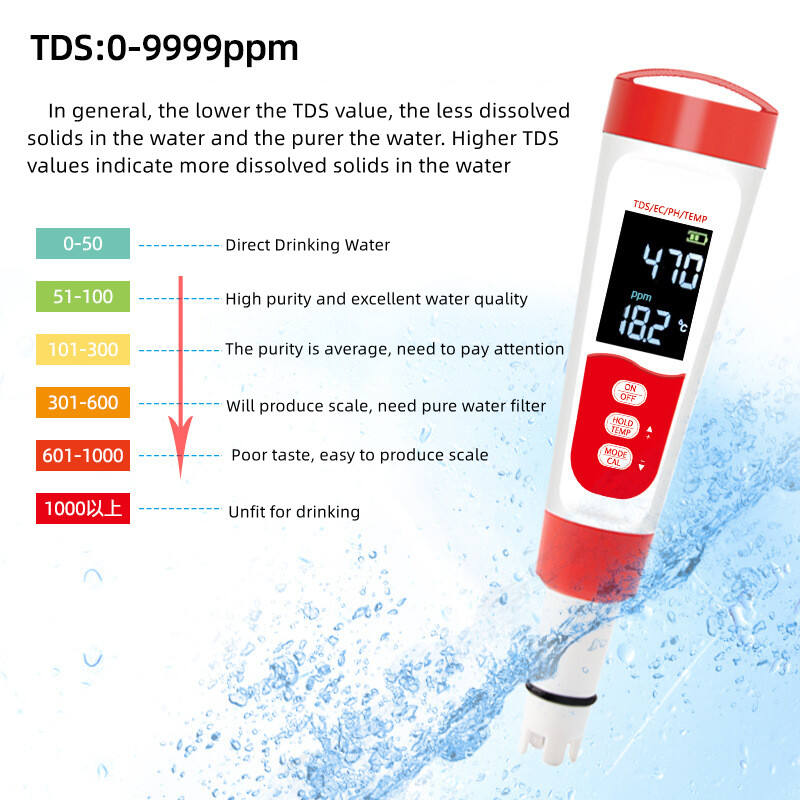

A PPM meter for hydroponics is an essential measurement tool that allows growers to monitor and maintain optimal nutrient concentrations in their hydroponic systems. This sophisticated device measures the total dissolved solids (TDS) in a nutrient solution by detecting the electrical conductivity (EC) of the water and converting it into parts per million (PPM). Modern PPM meters feature digital displays, waterproof casings, and automatic temperature compensation for accurate readings regardless of solution temperature. These meters typically offer measurement ranges from 0 to 9999 PPM, making them suitable for all stages of plant growth. The device works by inserting its probe into the nutrient solution, providing instant readings that help growers adjust nutrient levels precisely. Many contemporary models include additional features such as hold functions, calibration capabilities, and memory storage for previous measurements. The accuracy of these instruments typically falls within ±2% at room temperature, ensuring reliable data for maintaining optimal growing conditions. PPM meters have become indispensable in both commercial and hobby hydroponic operations, helping growers maintain consistent nutrient levels and prevent issues related to over or under-fertilization.