Essential Factors in Selecting Laboratory-Grade PH Testing Equipment

Accurate pH measurement is crucial across numerous industries, from water treatment and agriculture to food production and scientific research. A professional PH tester serves as an indispensable tool for precisely measuring the acidity or alkalinity of various substances. Whether you're a laboratory technician, environmental researcher, or quality control specialist, selecting the right professional PH tester can significantly impact the accuracy and reliability of your measurements.

The market offers a wide array of professional PH testers, each with distinct features and capabilities designed to meet specific testing requirements. Understanding the key factors that influence their performance and suitability for different applications will help you make an informed decision and ensure optimal results in your pH testing procedures.

Technical Specifications and Measurement Capabilities

Accuracy and Resolution Requirements

The accuracy of a professional PH tester is perhaps its most critical specification. High-end models typically offer accuracy rates of ±0.01 pH units, while standard versions might provide ±0.1 pH units. The resolution, which determines the smallest change in pH that can be detected, should align with your specific testing needs. For research laboratories and precise scientific applications, choosing a professional PH tester with high accuracy and fine resolution is essential.

Consider the measurement range of the device as well. While most professional PH testers cover the standard 0-14 pH range, some specialized models can measure beyond these limits. Ensure the tester's range capabilities match your testing requirements, especially if you work with extremely acidic or alkaline substances.

Temperature Compensation Features

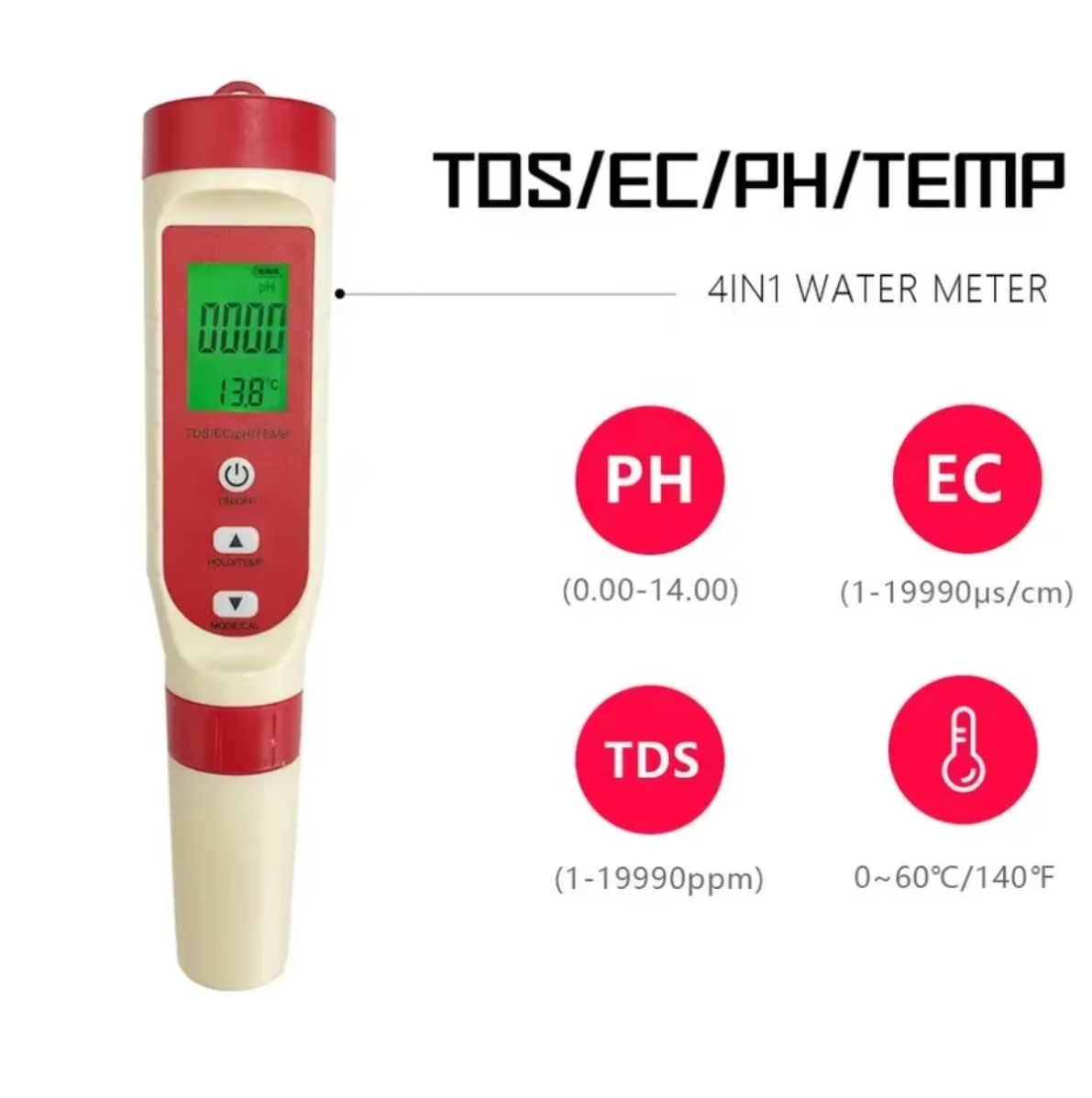

Temperature significantly affects pH measurements, making automatic temperature compensation (ATC) a vital feature in any professional PH tester. Advanced models incorporate sophisticated temperature sensors that automatically adjust readings based on sample temperature, ensuring accurate results across varying conditions. Look for devices that display both pH and temperature readings simultaneously for comprehensive monitoring.

Some professional PH testers offer manual temperature compensation options, which can be useful in specific applications or when working with samples at controlled temperatures. The temperature range and accuracy of the compensation system should match your operating conditions and precision requirements.

Design and Construction Quality

Durability and Protection Standards

The construction quality of a professional PH tester directly impacts its longevity and reliability in various working environments. Look for devices with robust housings, preferably with IP ratings indicating dust and water resistance. Models with IP67 or IP68 ratings offer excellent protection against harsh conditions and can withstand occasional submersion.

Consider the material quality of the electrode and housing. Premium professional PH testers often feature chemical-resistant materials and reinforced components that can withstand regular exposure to various substances. The durability of connection points, buttons, and display screens should also factor into your selection process.

Ergonomics and Ease of Use

The practical aspects of using a professional PH tester daily shouldn't be overlooked. An ergonomic design with intuitive controls and clear display readings can significantly improve work efficiency. Look for features like backlit displays for low-light conditions, large easy-to-read screens, and comfortable grip designs that reduce operator fatigue during extended use.

Consider the overall size and portability of the device, especially if you need to perform measurements in different locations. Some professional PH testers offer convenient carrying cases or holsters that protect the instrument while making it easily accessible when needed.

Calibration and Maintenance Features

Calibration Capabilities

Regular calibration is essential for maintaining the accuracy of any professional PH tester. Look for devices that offer multiple-point calibration options, typically ranging from 1-point to 5-point calibration. More calibration points generally result in better accuracy across the entire measurement range. The calibration process should be straightforward, with clear indicators for successful calibration and error notifications.

Advanced professional PH testers often include automatic buffer recognition, which simplifies the calibration process by identifying standard buffer solutions automatically. This feature helps prevent errors and saves time during routine calibration procedures. Consider models that store calibration data and provide calibration reminders to maintain regular maintenance schedules.

Electrode Maintenance and Replacement

The electrode is the heart of any professional PH tester, and its maintenance significantly affects measurement accuracy and device longevity. Choose models with easily replaceable electrodes to extend the instrument's useful life. Some advanced testers include electrode diagnostics that monitor electrode condition and alert users when replacement is needed.

Consider the availability and cost of replacement electrodes when selecting a professional PH tester. Some manufacturers offer specialized electrodes for specific applications, which can provide better performance but may come at a higher cost. The ease of cleaning and storing the electrode should also factor into your decision.

Data Management and Connectivity

Storage and Documentation Capabilities

Modern professional PH testers often include data logging capabilities that allow you to store measurement results for later analysis or documentation. Consider the storage capacity and the types of data that can be recorded, such as pH values, temperature readings, date and time stamps, and calibration records. Some models offer automatic data logging at set intervals, which can be valuable for monitoring trends or conducting long-term studies.

The ability to export data to computers or other devices can streamline documentation and reporting processes. Look for professional PH testers that offer USB connectivity, wireless data transfer, or compatibility with laboratory information management systems (LIMS) if these features align with your workflow requirements.

Software Integration and Analysis Tools

Advanced professional PH testers may come with dedicated software for data analysis and visualization. These tools can help identify trends, generate reports, and maintain detailed records of measurements and calibrations. Consider whether the software is user-friendly and compatible with your existing systems and whether it provides the analysis capabilities you need.

Some manufacturers offer mobile apps that can connect to their professional PH testers via Bluetooth or Wi-Fi, enabling remote monitoring and control. These features can be particularly useful in automated processes or when measuring pH in hard-to-reach locations.

Frequently Asked Questions

How often should I calibrate my professional PH tester?

The calibration frequency depends on usage intensity and accuracy requirements. For regular use, calibrate at least weekly or before each critical measurement session. For occasional use, monthly calibration may be sufficient. Always calibrate when measuring accuracy appears compromised or when switching between significantly different pH ranges.

What is the typical lifespan of a professional PH tester electrode?

With proper care and maintenance, a professional PH tester electrode typically lasts 12-18 months under regular use. However, this can vary significantly based on usage conditions, sample types, and maintenance practices. Harsh chemicals, extreme temperatures, and improper storage can reduce electrode life considerably.

How does temperature affect pH measurements?

Temperature influences both the behavior of the sample being measured and the response of the pH electrode. As temperature changes, the ionization of molecules in the sample can change, affecting its pH. Additionally, the electrode's response characteristics vary with temperature. This is why automatic temperature compensation is crucial for accurate measurements across different temperature conditions.